Menu

- Home

- YLM Group

- Products

- Technical Workshop

- Catalogue

- News

- Contact Us

Hot Products

CNC Fully Auto Tube Bender

We offer fully automatic pipe bender CNC-controlled machining of pipes with a diameter from 4mm to 220mm. These models 3,4,5,6,7,8 axial (hybrid models with electrical control in conjunction with the plumbing) and all-electric models in the 10-12 axis.

MoreSheet Laser cutting machine - Tube Bending Machines & Robotic Machining Manufacturer | YLM Group

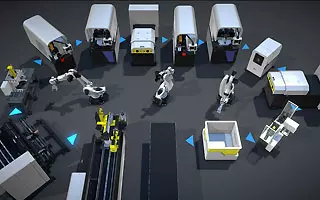

Located in Taiwan since 1976, YLM Group is a tube and pipe bending machine manufacturer. Their main machinery, include CNC electric tube bending machines, CNC electric R&L tube bending machines, CNC hybrid tube bending machines, end-forming machines and 6-axis vertical articulated mechanical arms, which are ISO 9001:2015 and CE MARK certified.

YLM provides advanced and practial solutions to customer who gets invovel of metal tubular bending, especially for the sector of transporatation of two/three/four wheelers, furniture tubular components, shipbuild and boiler parts, and some of havey industrial components. YLM Group's CNC, NC and conventional types of tube & pipe bending equipment has been sold worldwide with solid reputation. The innovative cold-bending technology and equipments solutions for companies in metal tube forming industries, especially automotive, furniture, heating, ship-building with tube od range from from 4 to 220 mm, tube w.t from 0.4 mm to 10 mm, the CLR from 0.6 to unlimited.

YLM Group has been offering customers high-quality CNC tube and pipe bending machines, both with advanced technology and 47 years of experience, YLM Group ensures each customer's demands are met.

Our apologies...

The page or document you are looking for could not be found.

- If you typed the url address, make sure the spelling is correct, most address are case sensitive.

- If you typed the keyword, make sure all words are spelled correctly or try different keywords.

English

English