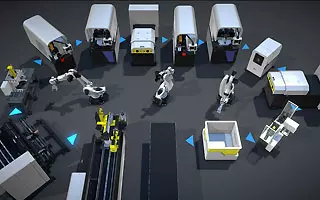

AMR ROBOT, AMR, AGV

Applicable industries

- Applicable Industries:

- Material handling and delivery (metal machining, automotive manufacturing, electronic assembling)

- Logistics and warehousing

Features and Benefits

- Features and benefits:

- Automatic obstacle avoidance, advanced multi anti-collison sensors eliminating human negligence.

- Autonomous movement for efficient operation.

- Digital tracking of delivery operations records.

- Automatic lifting and delivery of material rack, task system management, initiative path planning.

- Running with the automatic charger, raising the working efficiency up to 40%.

| Model | TM-300-JU | TM-600-JU | TM-1000-JU | |

|---|---|---|---|---|

| Rated load | 300 kg | 600 kg | 1000 kg | |

| Vehicle dimension: L/W/H | 750X540X230 mm | 930X660X250 mm | 1180X860X265 mm | |

| Weight | 92 kg | 155 kg | 300 kg | |

| Lifting height | 60 mm | 60 mm | 60 mm | |

| Minimum ground clearance | 25 mm | 25 mm | 25 mm | |

| Speed (empty/loaded) | 2.0/1.5 m/s | 1.9/1.3 m/s | 1.5/1.3 m/s | |

| Max. Gradeability (empty/loaded) | 5/3 % | 5/3 % | 5/3 % | |

| Minimum turning radius | 375 mm | 465 mm | 630 mm | |

| Minimum channel width | 950 mm | 1130 mm | 1460 mm | |

| Driving mode | Differential | Differential | Differential | |

| Power configuration | 48V (20Ah) | 48V (30Ah) | 48V (50Ah) | |

| Charging time | ≦2 hour | ≦2 hour | ≦2 hour | |

| Endurance time | 8 hour | 8 hour | 8 hour | |

| Navigation mode | Lidar SLAM | Lidar SLAM | Lidar SLAM | |

| Positioning accurary | ±10 mm | ±10 mm | ±10 mm | |

| Safe distance | 5 mm | 5 mm | 5 mm | |

| Communication mode | WIFI | WIFI | WIFI | |

English

English